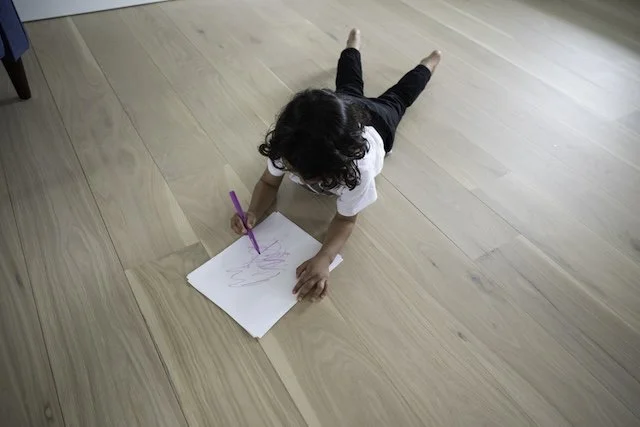

Site-Finished Hardwood

Choose Excellence

Site-finishing means we’ll install and finish the wood on-site at your property. This option means a precise finish that will sit smoothly and stably within its surroundings. We’ll also seal in the installation, leaving a firm finish that will last for many years to come.

Why Should You Choose Site-Finished Hardwood Floors?

Want the highest amount of customization and choice? Site-finished hardwood flooring will give you greater freedom to achieve your desired look.

With this process, you can choose the structure of your flooring, species, grade, installation pattern, and finishes. With site-finished floors, you can achieve a natural look that pre-finished flooring cannot match, as they lack the characteristic bevels and have a smoother appearance. Additionally, site-finished floors collect less dirt and dust compared to their pre-finished counterparts, making them easier to clean and maintain.

The customization process explained

First, you’ll be selecting the most appropriate hardwood for your project. There are many aspects to consider here, including longevity, surroundings, climate, and yes, personal taste is definitely going to play a big role.

As an example of some of the considerations, when it comes to the structural environment, hardwood works well with plywood but not so well with concrete. For concrete structures, engineered hardwood is more suitable.

Wood Species

Our workshop and studio offers a wide range of wood, with both local and international species available.

Every species has a distinct cellular structure, resulting in unique physical properties and choosing a specific wood species can impart a unique character to your home so it’s essential to understand the differences before making a decision.

Hardness

A hardness scale can help you understand each variety’s hardness and resistance, as well as which structures it suits.

Stability

The environment, including humidity, can have a big effect on your wood, leading to expansion and contraction at certain times of the year.

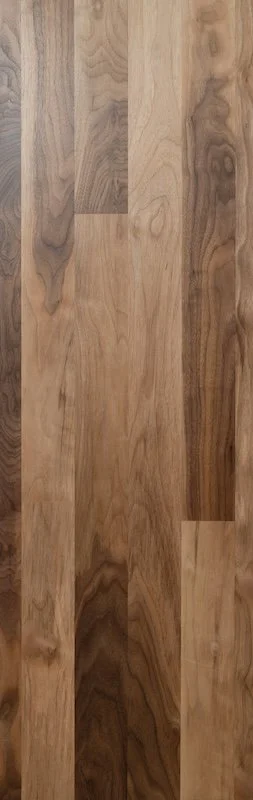

Natural Color

Every species has a different tone and shade, from light to dark and everything in between. Make sure the wood you choose complements your furnishings and your own taste.

Grain Pattern

The decision to choose a wood species with pronounced natural grain patterns is subjective and varies based on individual taste. Have a think about whether you prefer natural and more random grain patterns or something more uniform and plain.

Our Selection Of Wood Species To Choose From

White Oak

Red Oak

Hickory

American Cherry

Walnut

Australian Cypress

Ash

Brazilian Cherry

Wood Grades

rading is a method used to evaluate the appearance of wood and is determined by the presence of "character" markings or natural traits, as well as variation in color, mineral streaks, knots, or wormholes. Grades are not necessarily about quality, but about you and your home’s needs. For instance, some may prefer the uniformity of select grades, while others may lean towards a more rustic look that gives the floor character. It's worth noting that wood with fewer character markings is often more expensive, as less of the tree is used to make it.

Grades may vary by species*

Select & Better

exhibits very few imperfections or character markings. This grade is characterized by a uniform color with minimal knots or holes and longer, similar-length boards.

#1 Common

wider range of light and dark colors on different boards and includes some knots and holes, as well as varying lengths.

#2 Common

much greater variations in color with visible mineral streaks, and more visible and larger knots and worm holes.

Euro Character

Offers a broader range of coloring and natural characteristics than Select & Better. This grade allows for longer planks.

Finishing Your New Wood Flooring

Once your floor is ready for finishing, we’ll add one optional coat of stain and three coats of polyurethane in order to protect and preserve the natural beauty of the wood.

We offer a range of customized colors for site-finished hardwood and have a large variety of domestic and international species, such as oak, American cherry, and maple. Our team of expert advisors and installation professionals is here to provide you with personalized advice and guidance on the best color and finish for your home's interior design. Visit our showroom to see the range of options available to you and take the first step towards achieving the floor of your dreams.

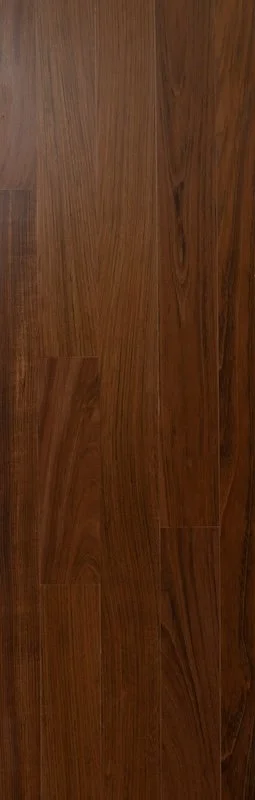

Stains

Staining helps to liven up the color of your hardwood floors and enhance their visual aesthetic. It's worth noting, however, that each wood species absorbs stain differently. Some species stain evenly, enhancing the natural grain of the wood, while others may appear splotchy or uneven.

It's crucial to sample how the stain reacts to your specific wood before applying it to your entire floor. This will give you a better understanding of the end result and ensure that you achieve the desired color and finish for your space. Our team of professionals can guide you through the staining process, providing expert advice on the best stain color and application technique to achieve the perfect result for your home. Trust us to help you achieve the stunning and customized hardwood floor you've been dreaming of.

Stains Galleries

Protective Coats Of Finish

The final step in the finishing process is applying a protective layer of polyurethane, which not only enhances the natural beauty of the wood but also provides durability and longevity. Our team of experts can help you decide which type of polyurethane is the right choice for your floors and provide guidance on the best application technique for your specific hardwood species. Water-based polyurethane is a popular alternative to oil-based polyurethane. This finish utilizes water as the base for carrying the polyurethane solids, rather than solvents. Like oil-based polyurethane, water-based polyurethane forms a hard protective film that enhances the natural beauty of your hardwood floors. Unlike oil-based polyurethane, water-based polyurethane begins milky-white in the can but dries clear. It imparts very little color to the wood, resulting in a natural, clear finish. Water-based finishes offer many of the same great advantages as oil-based finishes, but with less odor, fewer VOCs, and shorter drying and curing times.

Oil-based polyurethane utilizes petroleum and mineral solvents as the vehicle for the polyurethane solids, creating a hard and protective film that enhances the natural beauty of the wood. Unlike water-based polyurethane, oil-based polyurethane may impart a slightly yellow sheen, especially with multiple coats. However, this can be a desired effect in certain applications, adding warmth and depth to the floor's appearance. While oil-based polyurethane has a longer drying time and requires ventilation during application, it is still widely sold and a popular choice for high-traffic areas.